US20060159925A1 - High-intensity, persistent thermochromic compositions and objects, and methods for creating the same - Google Patents

High-intensity, persistent thermochromic compositions and objects, and methods for creating the same Download PDFInfo

- Publication number

- US20060159925A1 US20060159925A1 US11/311,289 US31128905A US2006159925A1 US 20060159925 A1 US20060159925 A1 US 20060159925A1 US 31128905 A US31128905 A US 31128905A US 2006159925 A1 US2006159925 A1 US 2006159925A1

- Authority

- US

- United States

- Prior art keywords

- thermochromic

- layer

- formulation

- preformed article

- materials

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Abandoned

Links

- GACGWRPHOKBIIE-UHFFFAOYSA-N CCC(C)CC1=CC=C(OC(=O)C2=CC=C(C)C=C2)C=C1 Chemical compound CCC(C)CC1=CC=C(OC(=O)C2=CC=C(C)C=C2)C=C1 GACGWRPHOKBIIE-UHFFFAOYSA-N 0.000 description 1

- YWVINFYPCWIGFT-UHFFFAOYSA-M CN(C)C1=CC=C(C(C2=CC=C(N(C)C)C=C2)C2=CC=C(N(C)C)C=C2C(=O)[O-])C=C1.CN(C)C1=CC=C(C2(C3=CC=C(N(C)C)C=C3)OC(=O)C3=CC(N(C)C)=CC=C32)C=C1 Chemical compound CN(C)C1=CC=C(C(C2=CC=C(N(C)C)C=C2)C2=CC=C(N(C)C)C=C2C(=O)[O-])C=C1.CN(C)C1=CC=C(C2(C3=CC=C(N(C)C)C=C3)OC(=O)C3=CC(N(C)C)=CC=C32)C=C1 YWVINFYPCWIGFT-UHFFFAOYSA-M 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K11/00—Luminescent, e.g. electroluminescent, chemiluminescent materials

- C09K11/06—Luminescent, e.g. electroluminescent, chemiluminescent materials containing organic luminescent materials

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63B—APPARATUS FOR PHYSICAL TRAINING, GYMNASTICS, SWIMMING, CLIMBING, OR FENCING; BALL GAMES; TRAINING EQUIPMENT

- A63B37/00—Solid balls; Rigid hollow balls; Marbles

- A63B37/0003—Golf balls

- A63B37/0023—Covers

- A63B37/0024—Materials other than ionomers or polyurethane

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63B—APPARATUS FOR PHYSICAL TRAINING, GYMNASTICS, SWIMMING, CLIMBING, OR FENCING; BALL GAMES; TRAINING EQUIPMENT

- A63B37/00—Solid balls; Rigid hollow balls; Marbles

- A63B37/0003—Golf balls

- A63B37/005—Cores

- A63B37/0051—Materials other than polybutadienes; Constructional details

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D5/00—Processes for applying liquids or other fluent materials to surfaces to obtain special surface effects, finishes or structures

- B05D5/06—Processes for applying liquids or other fluent materials to surfaces to obtain special surface effects, finishes or structures to obtain multicolour or other optical effects

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D7/00—Processes, other than flocking, specially adapted for applying liquids or other fluent materials to particular surfaces or for applying particular liquids or other fluent materials

- B05D7/50—Multilayers

- B05D7/52—Two layers

- B05D7/54—No clear coat specified

- B05D7/542—No clear coat specified the two layers being cured or baked together

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D7/00—Processes, other than flocking, specially adapted for applying liquids or other fluent materials to particular surfaces or for applying particular liquids or other fluent materials

- B05D7/50—Multilayers

- B05D7/52—Two layers

- B05D7/54—No clear coat specified

- B05D7/546—No clear coat specified each layer being cured, at least partially, separately

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K11/00—Luminescent, e.g. electroluminescent, chemiluminescent materials

- C09K11/02—Use of particular materials as binders, particle coatings or suspension media therefor

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K9/00—Tenebrescent materials, i.e. materials for which the range of wavelengths for energy absorption is changed as a result of excitation by some form of energy

- C09K9/02—Organic tenebrescent materials

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63B—APPARATUS FOR PHYSICAL TRAINING, GYMNASTICS, SWIMMING, CLIMBING, OR FENCING; BALL GAMES; TRAINING EQUIPMENT

- A63B2225/00—Miscellaneous features of sport apparatus, devices or equipment

- A63B2225/76—Miscellaneous features of sport apparatus, devices or equipment with means enabling use in the dark, other than powered illuminating means

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63B—APPARATUS FOR PHYSICAL TRAINING, GYMNASTICS, SWIMMING, CLIMBING, OR FENCING; BALL GAMES; TRAINING EQUIPMENT

- A63B37/00—Solid balls; Rigid hollow balls; Marbles

- A63B37/0003—Golf balls

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63B—APPARATUS FOR PHYSICAL TRAINING, GYMNASTICS, SWIMMING, CLIMBING, OR FENCING; BALL GAMES; TRAINING EQUIPMENT

- A63B43/00—Balls with special arrangements

- A63B43/06—Balls with special arrangements with illuminating devices ; with reflective surfaces

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2211/00—Chemical nature of organic luminescent or tenebrescent compounds

- C09K2211/10—Non-macromolecular compounds

- C09K2211/1003—Carbocyclic compounds

- C09K2211/1007—Non-condensed systems

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K2211/00—Chemical nature of organic luminescent or tenebrescent compounds

- C09K2211/10—Non-macromolecular compounds

- C09K2211/1018—Heterocyclic compounds

- C09K2211/1025—Heterocyclic compounds characterised by ligands

- C09K2211/1088—Heterocyclic compounds characterised by ligands containing oxygen as the only heteroatom

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31652—Of asbestos

- Y10T428/31663—As siloxane, silicone or silane

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31786—Of polyester [e.g., alkyd, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/31504—Composite [nonstructural laminate]

- Y10T428/31855—Of addition polymer from unsaturated monomers

- Y10T428/31935—Ester, halide or nitrile of addition polymer

Definitions

- thermochromic compositions comprising an effective amount of thermochromic materials formulated to yield change in color of high intensity.

- the present invention is also directed to thermochromic objects comprising at least one envirochromic layer, wherein said envirochromic layer comprises at least one thermochromic composition.

- Thermochromic objects may also additionally comprise at least one reflective layer, at least one colorant layer, and/or at least one protective layer.

- Such protective layers comprise photoluminescent fluorescent materials to retard photolytic degradation.

- the present invention is further directed to methods for creating thermochromic objects, said methods comprising the steps of obtaining a preformed article and applying thereto at least one envirochromic layer constructed by applying said thermochromic materials, and wherein one may additionally apply to said preformed article said reflective layer, and/or said colorant layer, and/or said protective layer.

- Desirable products are those that meet specific needs and/or provide added benefits to the consumer.

- These specific needs or added benefits may be safety controls or indicators, environmental information indicators, shelf life indicators, authentication and tamper indicators, fashion accessory benefits, and/or fun & entertainment benefits.

- These added benefits can be created, or indicators provided, by triggering a color change as a response to the product's environment.

- Envirochromic materials are those whose visible color changes due to emission, absorption reflection, or scattering of electromagnetic radiation. Such emission, absorption, reflection, or scattering of electromagnetic radiation results from a change in the material's environment. These changes, or “triggers,” include change in temperature, change in electromagnetic radiation, change in chemical environment, an electrical stimulus, etc.

- Color change can occur by changes in electromagnetic radiation, reflection, absorption or scattering.

- photochromism signifies color change triggered by electromagnetic radiation

- thermochromism signifies color change triggered by changes in temperature

- electrochromism signifies changes in color occurring due to gain or loss of electrons

- solvatochromism signifies color change resulting from changes in solvent polarity

- halochromism signifies color change caused by a change in pH

- ionochromism signifies color change caused by ions

- piezochromism signifies changes caused by mechanical pressure.

- Color change can also result from luminescent emissions.

- luminescent emissions we will use “luminescence” or “luminescent” to signify the color change.

- thermochromic temperature-triggered color changes as a consequence of changes in absorption reflection and/or scattering of electromagnetic radiation, hereinafter referred to as “thermochromic,” but also from luminescent emissions which will be designated as “luminescent” or “luminescence.”

- Thermochromism can be triggered, in general, by inorganic compounds, organic compounds, polymers, and sol-gels.

- thermochromic behavior arises from phase transition, change in ligand geometry, equilibria between different molecular structures, and change in the number of solvent molecules in the coordination sphere.

- Certain metal complex crystals comprising double salts of a transition metal such as cobalt, nickel, or manganese, and an aminic amide, such as hexamethylenetetramine, exhibit thermochromism. See, e.g., U.S. Pat. No. 4,717,710. These double salts discolor on releasing water when heated and resume the original color on absorption of moisture when cooled. Id.

- a transition metal such as cobalt, nickel, or manganese

- an aminic amide such as hexamethylenetetramine

- thermochromic temperature range is substantially from 50° C. to about 300° C. More specifically, the number of substances undergoing thermochromism at temperatures below 100° C. is limited to 2 or 3. For instance, in the case of Ag 2 HgI 4 , the thermochromism is from yellow to orange occurs at 50° C., and in the case of Cu 2 HgI 4 thermochromism from red to brown is brought about at 70° C. See, e.g., U.S. Pat. No. 4,028,118. Of course, the kind of color cannot be optionally chosen and the difference between colors before and after thermochromism is small. Moreover, since these metal complex crystals are not light-transmitting, it is not possible to use them as optical switches to hide/reveal an indicia, pattern or color in the layer below. Id.

- thermochromic materials These materials have heretofore been used as thermochromic materials but their applications are limited.

- thermochromism varies with molecular structure. It may be due to equilibrium between two molecular species, acid-base, keto-enol, lactim-lactam, or between stereoisomers or between crystal structures.

- Thermochromic liquid crystals show different colors at different temperature because of selective reflection of specific wavelength of electromagnetic radiation from their structure.

- these materials form a cholesteric liquid crystal.

- changes in temperature result in thermal expansion, which leads to a change in layer spacing and hence pitch, which results in a change in the wavelength of reflected light and hence a color change is observed with varying temperature.

- Thermochromic substances further include cholesteric liquid crystals and mixtures of cholesteric liquid crystals and nematic liquid crystals, but these substances also find greatly limited use because they are low in color density, have no selectivity in color and in color change temperature and are very expensive. See, e.g., U.S. Pat. No. 4,717,710.

- Liquid crystals generally exhibit thermochromism at temperatures ranging from ⁇ 10° C. to +200° C.

- the number of liquid crystals undergoing thermochromism at a temperature not exceeding 0° C. is very limited, namely 1 or 2.

- the color or thermochromism causing temperature cannot freely be chosen but is determined by the properties of the liquid crystals per se. These compounds are also chemically very sensitive; their properties are readily degraded upon contact with other substances.

- Thermochromic liquid crystal materials tend to be expensive and generally exhibit low color density. Hence, their use is not widespread, occurring in specialized situations

- Thermochromism arising from variations in stereoisomers in mostly associated with “overcrowded” ethylenes, such as Bianthrone, Dixanthylene, and Xanthylidenanthrone. These compounds are characterized by at least one ethylene group, a number of aromatic rings, and a hetero-atom, usually nitrogen or oxygen.

- the ethylene bond places a restriction on the molecular orientations possible, thereby increasing the energy barrier between different streoisomeric configurations.

- the temperature is increased, the molecule “switches” between different stereoisomers, this change being accompanied by a variation in color.

- thermochromism occurs at temperatures in excess of 150° C.

- bianthrone is colorless when solid, but forms green droplets above its melting point.

- the molecular rearrangement of an organic compound that arises from tautomerization can lead to an increase in the conjugation of the molecule, and consequently the formation of a new chromophore.

- Such molecular rearrangement can be effected by a change in temperature or by alteration of the polarity of the solvent and/or the pH of the system. Examples are, acid-base, keto-enol, and Lactim-Lactam equilibrium.

- thermochromic behavior Although fundamentally the chromism is pH-dependent, the temperature-dependence of the acid-base equilibrium means that pH sensitivity can result in thermochromic behavior. We present below one such example of crystal violet lactone.

- crystal violet Lactone does not exhibit thermochromism below a pH of 4. That is, even upon heating the ring opening does not occur and the colored form predominates. On the other hand, at higher pHs and upon heating equilibrium will shift to the left and the dye will become colorless.

- thermochromic system is one wherein molecular rearrangement occurs by a reaction between an electron donating compound referred to as a color former and an electron accepting compound referred to as a developer.

- compositions have the following advantages: (1) Thermochromic materials can be formulated for various colors; (2) The thermochromic materials gives a high color density; and (3) Depending on the kind of solvent, the color change temperature can be set over a wide range of low to high temperatures.

- thermochromic materials of this type generally comprise an electron donating compound, an electron accepting compound, and organic solvents to control the temperature and sensitivity of the thermochromic effect. It can be appreciated that since thermochromism is an equilibrium reaction, the two component systems can be very sensitive to their environment and hence are generally encapsulated to make them amenable to deployment in different formulations. See, e.g., U.S. Pat. Nos. 4,028,118; 4,421,560; 4,425,161; and 4,717,770.

- thermochromic materials which are generally very sensitive to their physical and chemical environment, which can comprise solvents, polymeric resin binders, stabilizing additives, pigments, dyes etc., which if not controlled, can quickly result in a degradation of the degree of color change, or even complete loss of thermochromic performance.

- thermochromic materials are encapsulated, to enable greater formulation flexibility for application to various substrates deploying a variety of techniques, the materials are still quite sensitive to their physical and chemical environment since the encapsulant is still porous.

- these materials are essential for the color change to be perceived as vibrant.

- thermochromic materials Even if the chemical environment does not impact the thermochromic materials, it can impact the capsule material. For example, the solvent can swell the polymeric capsule wall, thereby making it a scatterer of electromagnetic radiation. In cases where thermochromic materials are used as an optical switch, the changed color state will appear white and/or hazy instead of clear.

- thermochromic material environment is carefully selected so that the thermochromic performance is not degraded

- the solvents used can leach harmful materials from the substrate over which these materials are applied.

- thermochromic materials have generally been deployed as single layer applications, the color gamut is still fairly limited.

- pigments are added to colorants in order to expand the range of colors that can be achieved.

- color results from absorption of electromagnetic radiation creating colors with combinations of thermochromic materials of limited color range, and pigment colorants, is still quite restrictive in the range of bright colors that can be achieved.

- thermochromic materials are not only subject to photolytic degradation but by virtue of their sensitivity, need to be protected from mechanical forces such as abrasion, etc.

- thermochromic materials and mixtures of thermochromic materials will need to be adapted to provide the requisite color change.

- Thermochromic materials usually exist as solids or liquid crystals in a carrier medium.

- thermochromic materials When thermochromic materials are used as an optical switch, the theromochromic material needs to be formulated with clear resins and solvents that do not interact. Vibrant color layer formulations using solvents that do not leach are also desired.

- thermochromic objects also necessitates good adhesion to substrates and mechanical toughness such as scratch resistance, etc., specific requirements being dictated by the application.

- thermochromic materials and thermochromic objects created from such materials that can serve as safety indicators, fashion indicators, or create fun and entertainment by triggering temperature-activated color changes that are vibrant and impactful.

- the thermochromic objects can also be created in a variety of standard and emissive colors, also with high intensity.

- the thermochromic objects are also created to minimize photolytic degradation, do not degrade with moisture, and are mechanically robust, particularly in outdoor applications.

- thermochromic materials comprising an effective amount of thermochromic materials, at least one liquid carrier medium, at least one polymeric resin, and at least one formulation stabilizing additive, wherein said thermochromic materials are uniformly distributed within said formulation provide thermochromic formulations with high intensity and persistence.

- thermochromic formulation comprising an effective amount of thermochromic materials, at least one liquid carrier medium, at least one polymeric resin, and at least one formulation stabilizing additive, wherein said thermochromic materials are uniformly distributed within said formulation.

- the present invention is directed to a thermochromic formulation comprising an effective amount of thermochromic materials, at least one liquid carrier medium, at least one polymeric resin, and at least one formulation stabilizing additive, wherein said thermochromic materials are uniformly distributed within said formulation and wherein the theromchromic formulation has an FT of at least 90%.

- the present invention is directed to a thermochromic object comprising a performed article and at least one thermochromic layer, wherein the thermochromic layer results from the foregoing thermochromic formulations.

- the present invention is directed to a thermochromic object comprising a preformed article, at least one thermochromic layer, and at least one reflective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the reflective layer results from a reflective formulation, wherein the reflective layer is proximal to said preformed article, and wherein said thermochromic layer is distal to said preformed article.

- the present invention is directed to a thermochromic object comprising a preformed article, at least one thermochromic layer, at least one reflective layer, and at least one protective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the reflective layer results from a reflective formulation, wherein said protective layer results from a protective formulation, wherein the reflective layer is proximal to said preformed article, and wherein said protective layer is distal to said preformed article, and wherein said thermochromic layer is between said reflective layer and said protective layer.

- the present invention is directed to a thermochromic object comprising a preformed article, at least one thermochromic layer, and at least one protective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the protective layer results from a protective formulation, wherein the thermochromic layer is proximal to said preformed article, and wherein said protective layer is distal to said preformed article.

- the present invention is directed to a method for creating a thermochromic object, said method comprising the steps of obtaining a preformed article and applying to said preformed article at least one thermochromic layer, wherein said thermochromic layer results from the foregoing thermochromic formulations.

- the present invention is directed to a method for creating a thermochromic object, said method comprising the steps of obtaining a preformed article, applying to said preformed article at least one thermochromic layer, and applying to said preformed article at least one reflective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the reflective layer results from a reflective formulation, wherein the reflective layer is proximal to said preformed article, and wherein said thermochromic layer is distal to said preformed article.

- the present invention is directed to a method for creating a thermochromic object, said method comprising the steps of obtaining a preformed article, applying to said preformed article at least one thermochromic layer, applying to said preformed article at least one reflective layer, and applying to said preformed article at least one protective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the reflective layer results from a reflective formulation, wherein said protective layer results from a protective formulation, wherein the reflective layer is proximal to said preformed article, and wherein said protective layer is distal to said preformed article, and wherein said thermochromic layer is between said reflective layer and said protective layer.

- the present invention is directed to a method for creating a thermochromic object, said method comprising the steps of obtaining a preformed article, applying to said preformed article at least one thermochromic layer, and applying to said preformed article at least one protective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the protective layer results from a protective formulation, wherein the thermochromic layer is proximal to said preformed article, and wherein said protective layer is distal to said preformed article.

- FIG. 1 illustrates how absorption of ultraviolet radiation by a molecule excites it from a vibrational level in the electronic ground state to one of the many vibrational levels in the electronic excited state, such as singlet states and triplet states.

- FIG. 2 is a Jablonski Diagram illustrating processes that occur between the absorption and emission of electromagnetic radiation.

- FIG. 3 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformed article 1 with a thermochromic layer 2 applied thereto.

- FIG. 4 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformed article 1 with a reflective layer 3 and a thermochromic layer 2 applied thereto.

- FIG. 5 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformed article 1 with a theromchromic layer 2 and a protective layer 4 applied thereto.

- FIG. 6 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformed article 1 with a reflective layer 3 , a thermochromic layer 2 , and a protective layer 4 applied thereto.

- FIG. 7 is a stylized depiction of an embodiment of the invention whereby transfer technology is used to obtain the thermochromic object.

- FIG. 8 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformed article 1 with a reflective layer 3 , a first thermochromic layer 2 , a second thermochromic layer 5 , a first protective layer 4 , and second protective layer 6 applied thereto.

- FIG. 9 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformed article 1 with a reflective layer 3 , a first thermochromic layer 2 , a second thermochromic layer 5 , and a first protective layer 4 applied thereto.

- FIG. 10 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformed article 1 with a reflective layer 3 , a first thermochromic layer 2 , a first protective layer 4 , and second protective layer 6 applied thereto.

- thermochromic formulations As noted above, the present invention generally relates to thermochromic formulations, thermochromic objects comprising preformed articles onto which said thermochromic formulations have been applied, and to methods for creating said thermochromic objects.

- Luminescence is defined as the emission of electromagnetic radiation from any substance. Luminescence occurs from electronically excited states. As seen in FIG. 1 , absorption of ultraviolet radiation by a molecule excites it from a vibrational level in the electronic ground state to one of the many vibrational levels in the electronic excited states. The electronic states of most organic molecules can be divided into singlet states and triplet states.

- plasma state refers to when all electrons in the molecule are spin-paired.

- triplet state refers to when one set of electron spins is unpaired.

- the excited state is usually the first excited state. A molecule in a high vibrational level of the excited state will quickly fall to the lowest vibrational level of this state by losing energy to other molecules through collision. The molecule will also partition the excess energy to other possible modes of vibration and rotation.

- Luminescent materials are those which emit electromagnetic radiation. Characterizing luminescent materials requires consideration of: (1) the excitation source, (2) the nature of the emission, and (3) whether or not additional stimulation is required to cause emission.

- luminescent materials excited by electromagnetic radiation are referred to herein as “photoluminescent.”

- Luminescent materials excited by electrical energy are referred to herein as “electroluminescent.”

- Luminescent materials excited by a chemical reaction are referred to herein as “chemiluminescent.”

- this may be either fluorescence or phosphorescence.

- a “fluorescent” material stores electromagnetic radiation and releases it rapidly, in about 10 ⁇ 12 seconds or less.

- a “phosphorescent” material stores electromagnetic radiation and releases it gradually, in about 10 ⁇ 8 seconds or more.

- FIG. 2 Processes that occur between the absorption and emission of electromagnetic radiation are usually illustrated using a Jablonski Diagram, such as the one found in FIG. 2 .

- Ground, first, and second electronic states are depicted in FIG. 2 by S 0 , S 1 , and S 2 , respectively.

- the fluorophores can exist in a number of vibrational energy levels, denoted by 0, 1, 2, etc. Transitions between states are depicted in FIG. 2 as vertical lines to illustrate the instantaneous nature of electromagnetic radiation absorption.

- Fluorescence occurs when a molecule returns, by emission of a photon, from the excited singlet state to the electronic ground state. If the photon emission occurs between states of the same spin state, that is, from S 1 to S 0 , it is characterized as fluorescence.

- Phosphorescence occurs when a molecule goes from the ground state to a metastable state such as T1, a triplet state, and then the metastable state slowly decays back to the ground state S 0 , via photon emission. Hence, if the spin states between initial and final energy levels are different, that is emission occurs between T 1 to S 0 , it is characterized as phosphorescence.

- thermochromic is defined as characterizing a change in absorption, reflection, and/or scattering of electromagnetic radiation with a change in temperature to cause a change in the perceived color, wherein the color change may be from colorless to colored, or colored to colorless, or from one color to another.

- Thermochromic materials are defined to mean materials that undergo a change in absorption, reflection, and/or scattering of electromagnetic radiation with a change in temperature to cause a change in the perceived color of the materials wherein the color change may be from colorless to colored, or colored to colorless, or from one color to another.

- Thermochromic objects are defined to mean objects that undergo a change in absorption, reflection, and/or scattering with a change in temperature to cause a change in the perceived color of the object wherein the color change may be from colorless to colored, or colored to colorless or from one color to another.

- “Negative thermochromism” is defined to describe a temperature-triggered color change resulting from a change in absorption, reflection, and/or scattering wherein the color change is from a colored state to a colorless state.

- Pelsitive thermochromism is defined to describe a temperature-triggered color change resulting from a change in absorption, reflection, and/or scattering of electromagnetic radiation wherein the color change is from a colorless to colored state.

- Nemism is defined to describe a temperature-triggered color change resulting from a change in absorption, reflection, and/or scattering of electromagnetic radiation wherein the color change is from one color to another color.

- Liquid carrier medium is a liquid that acts as a carrier for materials distributed in a solid state and/or dissolved therein.

- a “formulation” is a liquid carrier medium, as defined above, comprising at least one material either dissolved and/or distributed in a solid state within said liquid carrier medium.

- a “dispersion” is a formulation, as defined above, wherein said material is a solid distributed in the liquid carrier medium.

- thermochromic formulation is a formulation, as defined above, which additionally comprises thermochromic materials as defined above.

- thermochromic layer is a film resulting from at least one thermochromic formulation that is substantially dry, as characterized by the residual liquid carrier medium being in the range of 1-5 weight % of the total weight of the film.

- a “reflective formulation” is a formulation, as defined above, which comprises at least a polymeric resin in a liquid carrier medium, as defined above, and further comprises at least one colorant (white or non-white).

- a “reflective layer” is a film resulting from at least one reflective formulation that is substantially dry, as characterized by the residual liquid carrier medium being in the range of 1-5 weight % of the total weight of the film.

- a “white reflectance layer” is one that reflects 95% of visible electromagnetic radiation incident upon it.

- a “protective formulation” is a formulation, as defined above, which comprises at least a polymeric resin selected for environmental or mechanical protection of the underlying article, upon application onto said article.

- a “protective layer” is a film resulting from at least one protective formulation that is substantially dry, as characterized by the residual liquid carrier medium being in the range of 1-5 weight % of the total weight of the film.

- a “stabilizing additive” is a material added to a formulation comprising solid particles or a dispersion to uniformly distribute, prevent agglomeration, and/or prevent settling of solid materials in said dispersion in said liquid carrier medium to result in an enhancement of luminous intensity.

- Such stabilizing additives generally comprise dispersants and/or rheology modifiers.

- a “preformed article” is any article onto which at least one layer may be applied.

- a preformed article may be rigid or flexible.

- visible electromagnetic radiation is characterized by electromagnetic radiation with wavelengths in the region of 400 nanometers (“nm”) to 700 nm.

- FT Frm Transmissivity

- Photolytic degradation is deterioration, degradation, or change in properties, such as observed color, that is initiated by electromagnetic radiation.

- thermochromic materials that are formulated to be liquid mixtures with stabilizing additives comprising polymeric resin binders, dispersants, rheology modifiers, and wetting agents so as to be highly transmissive of visible electromagnetic radiation in the colorless thermochromic state upon application to any article.

- the present invention also relates to the use of photoluminescent fluorescent pigment materials to render color or aid in rendering color upon triggering of thermochromic materials into a colorless state.

- the present invention also relates to the use of the luminescent fluorescent dye materials such that they exist as solid solutions in the polymeric resin matrix, thereby creating high ratio of emission per unit weight of material deployed for rendering color or aid in rendering color upon triggering of the thermochromic materials into a colorless state

- the present invention also relates to the use of photostabilizers either singly or in combination or with a combined functionality in a single molecule to retard the photolytic degradation of said thermochromic and photoluminescent fluorescent materials cited above.

- thermochromic objects comprising at least one thermochromic layer, wherein said thermochromic layer is highly transmissive of visible electromagnetic radiation and wherein the thermochromic materials have been triggered into a colorless state.

- thermochromic objects comprising at least one thermochromic layer, as defined above, but which may additionally comprise photoluminescent fluorescent pigments, dyes, or both, as described above.

- thermochromic objects comprising at least one thermochromic layer, as defined abov,e but which may additionally comprises photostabilizers, as described above

- thermochromic object which comprises a thermochromic layer, as defined above, wherein the thermochromic layer functions as an optical switch to transition from either a colored state to a colorless state or from a colorless state to a colored state.

- thermochromic object which comprises a reflective layer comprising polymeric resin and white or colored pigments, wherein the reflective layer is highly reflective of unabsorbed visible electromagnetic radiation and wherein such reflective layer is deployed in conjunction with a thermochromic layer.

- thermochromic objects comprising a reflective layer, as defined above, and additionally comprising photoluminescent fluorescent pigments wherein the reflective layer is highly reflective of unabsorbed visible electromagnetic radiation.

- thermochromic object comprising a reflective layer, as defined abov,e and additionally comprising photoluminescent fluorescent dyes wherein the photoluminescent fluorescent dye exists as a solid solution in polymeric matrix wherein the reflective layer is highly reflective of unabsorbed visible electromagnetic radiation.

- thermochromicobject comprising a reflective layer as defined above which additionally comprises photostabilizers as defined above to retard the photolytic degradation of said thermochromic and photoluminescent fluorescent materials cited above

- thermochromic object comprises at least one reflective layer and at least one thermochromic layer

- the reflective layer is applied first, so that it is proximal to the preformed article.

- the thermochromic layer is applied after the reflective layer, so that said thermochromic layer is distal to said preformed article. If transfer technology is used, it must be used such that the result is the same.

- thermochromic object comprising at least one protective layer which comprises a polymeric resin and wherein the protective layer is deployed in conjunction with an thermochromic layer and wherein the protective layer provides physical protection to the thermochromic layer.

- thermochromic object comprising at least one protective layer as defined above but which additionally comprises photostabilizers as described above.

- thermochromic object comprises at least one thermochromic layer and at least one protective layer

- the thermochromic layer is applied first, so that it is proximal to said preformed article.

- the protective layer is applied after the thermochromic layer, so that said protective layer is distal to said preformed article. If transfer technology is used, it must be used such that the result is the same.

- thermochromic object comprises at least one reflective layer, at least one thermochromic layer, and at least one protective layer

- the reflective layer is applied first, so that it is proximal to said preformed article.

- the thermochromic layer is applied next and then the protective layer is applied. Therefore, the reflective layer is proximal to the preformed article, the protective layer is distal to said preformed article, and said thermochromic layer is between said reflective layer and said protective layer. If transfer technology is used, it must be used such that the result is the same.

- the present invention also relates to the method of making a thermochromic object with at least one thermochromic layer.

- the present invention also relates to the method of making a thermochromic object with at least one reflective layer and one thermochromic layer.

- the present invention also relates to the method of making a thermochromic object with at least one thermochromic layer and at least one protective layer.

- the present invention also relates to the method of making a thermochromic object with at least one colorant layer and at least one thermochromic layer.

- the present invention relates to the method of making a thermochromic object with at least one reflective layer, at least one thermochromic layer and at least one protective layer.

- the present invention relates to the method of making a thermochromic object with at least one colorant layer, at least one thermochromic layer and at least one protective layer.

- the present invention relates to the method of making a thermochromic object with at least one reflective layer, at least one colorant layer, at least one thermochromic layer and at least one protective layer.

- New products have surprisingly been developed that address the problems associated with various compounds and their uses, including developing products which have color changing indicators based on thermochromic, fluroscent photochromic, phosphorescent photochromic compounds or a combination thereof and that are constructed from a variey of substrate materials such as PVC acrylics, urethanes polyester, nylon, etc.

- the substrate or surface construction materials or components may be rigid or flexible.

- a system construction has also been developed such that the visual impact of the color change is striking, the indicator indicia are robust, the applied images patterns or indicia are photolytically stable and the product is not only durable for the user but also environmentally stable.

- These new products are also desirable and useful to consumers in many fields of use, including food products, entertainment, sports, transportation, weather protection, decorating, indoor and outdoor sanitation or a combination thereof.

- a multilayer system construction or layered material has been designed so as to create a visually striking impact of the color change, to be durable with respect to scratches and abrasions and to have weatherometric robustness, such as photolytic stability and atmospheric stability for the indicator indicia or images.

- One contemplated embodiment comprises a three functional layer structure with a base layer providing functionality for maximizing or that maximizes the desired visual impact of the color change of at least part of the layered material, a thermochromic layer providing functionality for triggering a state change that is, either colorless to colored, or colored to colorless, or from one color to another, and a protective layer that provides functionality for handling and weatherometric robustness for the underlying image.

- the protective layer can also provide a visual enhancement function when desired by providing a reflective component or gloss for image viewing.

- the base functional layer may produce the desired functionality either by a single or multiple layers of material, depending on the application and product.

- the base layer may be constructed either by blending the final color dye or pigment before fabrication of the layered material, such as by extrusion or molding or formation of plastic, glass, paper etc., or by a coating application process such as gravure, flexo, roll or blade coating etc., or by printing application processes such as screen printing or pad printing etc.

- a base layer construction would to apply a layer containing a dye or pigment material including one or more fluorescent dyes or pigments that will render a brilliant final color.

- the thermochromic layer (applied on top of this layer) would generally function as an optical switch going from colored to colorless.

- thermochromic layer having the appropriate dye or pigment for the desired visual impact.

- Another application of a base layer construction is where the base layer contains just a white reflective pigment coating to maximze the color rendering of the thermochromic materials. In this type of application the thermochromic layer would go from either colorless to colored or from one color to another.

- the base layer may also comprise multiple layers.

- An example of a two layer base functional layer is contemplated when the base layer is being applied to a rigid or flexible plastic or other material containing a strong absorbing color different from the final color.

- the base layer will consist of a hidden layer consisting of a white reflective pigment application followed by the layer rendering the final color such as that described above.

- the base functional layer could become a three layer construction. In this case, one has to first create a desired oversized (oversized relative to final color image) contrast color image followed by a white reflective image followed by final color image application.

- the base layer in addition to serving the function of enhancing the visual impact of the final color, will also serve as a platform for the additional layers and/or functional layers. Therefore, it is important to consider the components of the base layer with respect to the components of additional layers in order to avoid color bleeding, undesirable chemical reactions between layers of materials and deterioration of the desired visual impact of the layered materials.

- the second layer applied on top of the base layer will contain the thermochromic layer.

- the thermochromic layer may have one or more layers, where the layer or layers comprise at least one layer of envirochromic dyes, pigments or inks.

- Envirochromic dyes, pigments or inks are those that change color or texture with a changing environment, such as heat, cold, rain, sunshine, UV rays, snow, dark, light or a combination thereof.

- Envirochromic dyes, pigments or inks are contemplated to be those described herein earlier, conventional envirochromic dyes, pigments or inks, envirochromic dyes, pigments or inks that are yet to be developed or a combination thereof.

- Envirochromic inks, dyes and pigments may be clear until triggered, opaque until triggered or a particular color until triggered. Once triggered by an environmental condition, the ink, dye or pigment will change—whether it changes from clear to opaque or colored, from opaque to clear or colored or from colored to opaque or clear.

- Dispersing agents are surface-active substances of anionic, cationic, or neutral structure. These substances are added in a small amount, either directly to the solid or to the dispersion medium. Furthermore, it is known that even after complete deflocculation of the solid agglomerates into primary particles, re-agglomeration occurs after the dispersion process. In such a case, the effort expended to produce a dispersion is partially or completely negated.

- amino- and amide-functional poly- and oligocopolymers based on polyamines and polycaprolactones are used for the dispersion of magnetic pigments.

- European Patent No. 0 713 894 describes the use of amino-functional polylactones for coatings and printing inks.

- amine-functional polyacrylates such as those disclosed in European Patent No. 0 311 157 and in U.S. Pat. No. 3,980,602 are used for the stabilisation of organic and inorganic pigments.

- Amine-functional polymers based on polyisocyanates constitute a further group. See, e.g., European Patent Nos. 0 159 678 and 0 438 836.

- Suitable dispersing aids that minimize agglomeration require very low levels of energy are cited for example an acrylic acid-acrylamide polymer such as those cited in U.S. Pat. No. 6,596,816, incorporated herein by reference for all purposes, or salts of an amine functional compound and an acid such as those cited in U.S. Pat. No. 6,111,054, also incorporated herein by reference for all purposes.

- “Rheology Modifiers” are those substances which generally can build viscosity in liquid dispersion formulations, thereby retarding settling of pigment materials while at the same time significantly lowering viscosity upon application of shear, to enhance smooth applicability of such formulations onto articles.

- materials such as colloidal silica or fumed silica and magnesium aluminum silicate clays, such as bentonite, not only as thixotropic modifiers to prevent sagging and running of luminescent formulation as it is applied to the object but also as suspending fillers, that is, for minimizing settling of dense pigment particles such as phosphor particles. See, e.g., U.S. Pat. No. 6,207,077.

- thermochromic layer The bigger disadvantage of their use in luminescent coatings such as the thermochromic layer is that they lead to turbidities and haze rather than transparent coatings. Moreover, handling dry pulverulent products which give rise to dusts in the course of processing is undesirable.

- the present invention employs polymeric urea-urethanes in aprotic polar solvents as rheology modifiers.

- This class of rheology modifiers can be used satisfactorily, that is without any scattering of electromagnetic radiation, and without any significant build up of viscosity. Thus, this class serves not only as rheology modifiers but also to minimize settling of the dense pigment particles. Examples of such urea-urethanes can be found, for example, in U.S. Pat. No. 6,617,468 and U.S. Pat. No. 6,870,024, incorporated herein by reference for all purposes.

- the resulting surface may not be smooth. Instead, the surface may be less structured, referred to as having a wavy surface or as having an orange peel-like surface. These surfaces may be finely structured, with a short wave, or coarsely structured, with a long wave.

- the structure depends on the nature and composition of the coating compositions; for example, on whether these coating compositions comprise solvents or else are solvent-free, as in the case of powder coating materials.

- these coating compositions comprise solvents or else are solvent-free, as in the case of powder coating materials.

- powder coating materials it is absolutely necessary to add leveling agents, since without these leveling agents it is impossible to achieve a surface which is in any way smooth.

- poly(meth)acrylates and polysiloxanes which may be used as leveling promoters for coatings.

- the compounds generally comprise polydimethylsiloxanes, polymethylalkylsiloxanes, or else polyether- or polyester-modified polydimethyl- or polymethylalkylsiloxanes.

- the products used possess in some cases molecular weights of up to 100,000.

- the action of all these products is based on surface activity at the liquid/gas interface: owing to a certain incompatibility with the actual binder of the coating system, these products adopt an orientation to the interface. This incompatibility may be increased by raising the molecular weight of these polymers.

- a disadvantage then, however, is that owing to this incompatibility there can be cases wherein the scattering of electromagnetic radiation or haze of the layer becomes high, thereby resulting in significant reduction in luminous intensity.

- the present invention employs branched polymers comprising a free-radically or ionically polymerized base molecule into which monoethylenically unsaturated macromonomeric units have been incorporated by copolymerization. Examples of such polymers may be found in U.S. Pat. No. 6,710,127, incorporated herein by reference for all purposes.

- Deaerators are those substances which minimize entrained air.

- Defoamers are those substances that allow easier dissipation of entrained air.

- a significant amount of air entrainment can cause scattering of electromagnetic radiation and, hence, a reduction in luminous intensity.

- thermochromic pigment in a binder of nitrocellulose and diluted with 2-methoxyethanol. This gave pigment solids of 40% of dry pigment to 60% Nitrocellulose binder. The solids were contained in a solvent mixture at 45% solids. This material was coated over plasticized PVC to give a dry coating thickness of 18 microns using a screen printing process.

- the color of the thermochromic pigment at room temperature was selected so that it contrasted the color of the PVC.

- the opacity of the thermochromic layer at room temperature masked the PVC layer below it. The thermochromic layer became translucent when heated through normal body contact to reveal the contrasting base color of the PVC underneath.

- thermochromic pigment in 48% Nitrocellulose binder.

- the pigment and binder were prepared in a solvent mixture containing Toluene, Hexane, and Hydrocarbon solvents at a solids content of 40%. This material was applied using a silk screen to give a dry coating thickness of 22 microns.

- a yellow fluorescent pigment was dispersed in 2-methoxyethanol at 50% solids using the wetting agent TegoWet 550. This dispersion was added to an acrylic binder (NeoCryl B-735) to give solids of 20% in 2-methoxyethanol.

- the ink was then applied to plasticized PVC using a screen print to achieve a 15 micron thickness, which provided for an image that contrasted the base color of the PVC. Over this was applied the formulation from Example 2 at a thickness of 26 microns.

- the color of the thermochromic layer at room temperature contrasted with the fluorescent layer below it. In this case, the thermochromic layer was dark blue compared to the fluorescent yellow of the layer below the thermochromic layer.

- the opacity of the thermochromic layer masked the fluorescent layer below it. The image was such that when warmed, the thermochromic pigment became translucent and revealed the fluorescent layer printed underneath.

- Thermochromic pigment was mixed with 10% 2-methoxyethanol and then dispersed in plastisol to give a pigment concentration of 40% in the final mixture. This was then applied over a polyester fabric using a applicator to give a 1 mil ending thickness.

Abstract

Disclosed are thermochromic formulations, comprising an effective amount of thermochromic materials, which exhibit high luminous intensity and persistence. Also disclosed are thermochromic objects formed by applying at least one thermochromic layer, formed from thermochromic formulations, to preformed articles. Further disclosed are methods for creating thermochromic objects.

Description

- This application claims priority to U.S. Provisional Patent Application Ser. No. 60/637,535, filed Dec. 20, 2004 (Attorney Docket No. 7044531001), titled, “Layered Envirochromic Materials, Applications and Methods of Preparation Thereof,” which is incorporated by reference herein for all purposes.

- 1. Field of the Invention

- The present invention is directed to thermochromic compositions comprising an effective amount of thermochromic materials formulated to yield change in color of high intensity. The present invention is also directed to thermochromic objects comprising at least one envirochromic layer, wherein said envirochromic layer comprises at least one thermochromic composition. Thermochromic objects may also additionally comprise at least one reflective layer, at least one colorant layer, and/or at least one protective layer. Such protective layers comprise photoluminescent fluorescent materials to retard photolytic degradation. The present invention is further directed to methods for creating thermochromic objects, said methods comprising the steps of obtaining a preformed article and applying thereto at least one envirochromic layer constructed by applying said thermochromic materials, and wherein one may additionally apply to said preformed article said reflective layer, and/or said colorant layer, and/or said protective layer.

- 2. Description of the Related Art

- Modern consumers are looking for added information and features from the products that they purchase. Desirable products are those that meet specific needs and/or provide added benefits to the consumer. These specific needs or added benefits may be safety controls or indicators, environmental information indicators, shelf life indicators, authentication and tamper indicators, fashion accessory benefits, and/or fun & entertainment benefits. These added benefits can be created, or indicators provided, by triggering a color change as a response to the product's environment.

- Envirochromic materials are those whose visible color changes due to emission, absorption reflection, or scattering of electromagnetic radiation. Such emission, absorption, reflection, or scattering of electromagnetic radiation results from a change in the material's environment. These changes, or “triggers,” include change in temperature, change in electromagnetic radiation, change in chemical environment, an electrical stimulus, etc.

- Color change can occur by changes in electromagnetic radiation, reflection, absorption or scattering. Thus, for example, photochromism signifies color change triggered by electromagnetic radiation; thermochromism signifies color change triggered by changes in temperature; electrochromism signifies changes in color occurring due to gain or loss of electrons; solvatochromism signifies color change resulting from changes in solvent polarity; halochromism signifies color change caused by a change in pH; ionochromism signifies color change caused by ions; tribochromism caused by changes in mechanical friction; and piezochromism signifies changes caused by mechanical pressure.

- Color change can also result from luminescent emissions. Hence, when dealing with color changes resulting from emissions, we will use “luminescence” or “luminescent” to signify the color change.

- This invention deals with color changes not only resulting from temperature-triggered color changes as a consequence of changes in absorption reflection and/or scattering of electromagnetic radiation, hereinafter referred to as “thermochromic,” but also from luminescent emissions which will be designated as “luminescent” or “luminescence.”

- Thermochromism can be triggered, in general, by inorganic compounds, organic compounds, polymers, and sol-gels.

- Inorganic Compound Thermochromism

- Many metals and inorganic compounds are known to exhibit thermochromic behavior either as solids or in solution. It has been suggested that such thermochromic behavior arises from phase transition, change in ligand geometry, equilibria between different molecular structures, and change in the number of solvent molecules in the coordination sphere.

- Certain metal complex crystals comprising double salts of a transition metal such as cobalt, nickel, or manganese, and an aminic amide, such as hexamethylenetetramine, exhibit thermochromism. See, e.g., U.S. Pat. No. 4,717,710. These double salts discolor on releasing water when heated and resume the original color on absorption of moisture when cooled. Id.

- However, in these metal complex crystals, the thermochromic temperature range is substantially from 50° C. to about 300° C. More specifically, the number of substances undergoing thermochromism at temperatures below 100° C. is limited to 2 or 3. For instance, in the case of Ag2 HgI4, the thermochromism is from yellow to orange occurs at 50° C., and in the case of Cu2 HgI4 thermochromism from red to brown is brought about at 70° C. See, e.g., U.S. Pat. No. 4,028,118. Of course, the kind of color cannot be optionally chosen and the difference between colors before and after thermochromism is small. Moreover, since these metal complex crystals are not light-transmitting, it is not possible to use them as optical switches to hide/reveal an indicia, pattern or color in the layer below. Id.

- These materials have heretofore been used as thermochromic materials but their applications are limited.

- Organic Compound Thermochromism

- The mechanism responsible for thermochromism varies with molecular structure. It may be due to equilibrium between two molecular species, acid-base, keto-enol, lactim-lactam, or between stereoisomers or between crystal structures.

- Thermochromic liquid crystals show different colors at different temperature because of selective reflection of specific wavelength of electromagnetic radiation from their structure. In an appropriate temperature range intermediate between a low-temperature crystalline phase and a high-temperature isotropic liquid phase, these materials form a cholesteric liquid crystal. In a cholesteric liquid crystal, changes in temperature result in thermal expansion, which leads to a change in layer spacing and hence pitch, which results in a change in the wavelength of reflected light and hence a color change is observed with varying temperature. We present below an example of such a material that is used in the manufacture of a thermochromic printing ink.

- Thermochromic substances further include cholesteric liquid crystals and mixtures of cholesteric liquid crystals and nematic liquid crystals, but these substances also find greatly limited use because they are low in color density, have no selectivity in color and in color change temperature and are very expensive. See, e.g., U.S. Pat. No. 4,717,710.

- Liquid crystals generally exhibit thermochromism at temperatures ranging from −10° C. to +200° C. However, the number of liquid crystals undergoing thermochromism at a temperature not exceeding 0° C. is very limited, namely 1 or 2. The color or thermochromism causing temperature cannot freely be chosen but is determined by the properties of the liquid crystals per se. These compounds are also chemically very sensitive; their properties are readily degraded upon contact with other substances.

- Thermochromic liquid crystal materials tend to be expensive and generally exhibit low color density. Hence, their use is not widespread, occurring in specialized situations

- Thermochromism arising from variations in stereoisomers in mostly associated with “overcrowded” ethylenes, such as Bianthrone, Dixanthylene, and Xanthylidenanthrone. These compounds are characterized by at least one ethylene group, a number of aromatic rings, and a hetero-atom, usually nitrogen or oxygen. The ethylene bond places a restriction on the molecular orientations possible, thereby increasing the energy barrier between different streoisomeric configurations. As the temperature is increased, the molecule “switches” between different stereoisomers, this change being accompanied by a variation in color. For a majority of compounds that exhibit this behavior, thermochromism occurs at temperatures in excess of 150° C. For example, bianthrone is colorless when solid, but forms green droplets above its melting point.

- The molecular rearrangement of an organic compound that arises from tautomerization can lead to an increase in the conjugation of the molecule, and consequently the formation of a new chromophore. Such molecular rearrangement can be effected by a change in temperature or by alteration of the polarity of the solvent and/or the pH of the system. Examples are, acid-base, keto-enol, and Lactim-Lactam equilibrium.

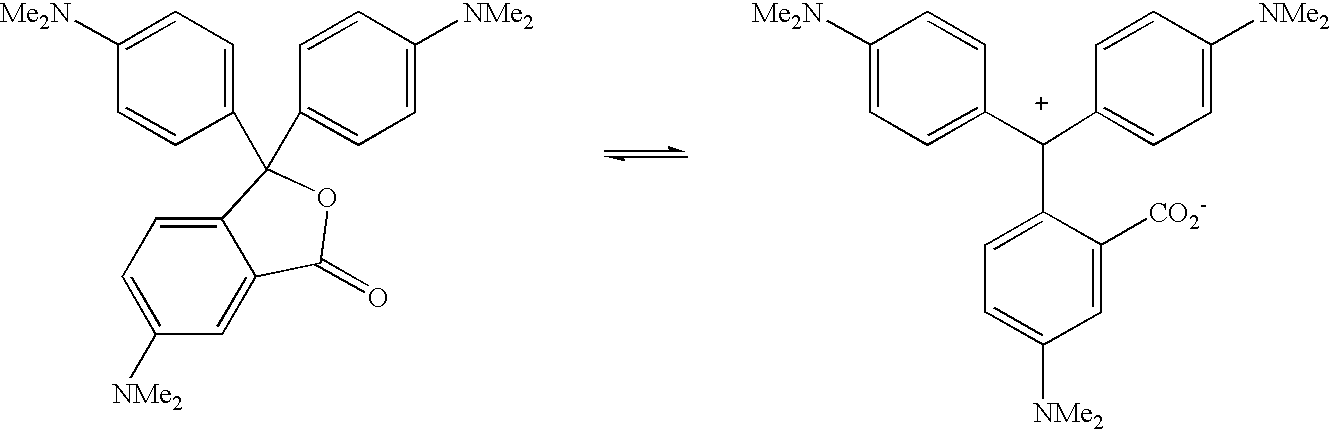

-

- It should be noted that crystal violet Lactone does not exhibit thermochromism below a pH of 4. That is, even upon heating the ring opening does not occur and the colored form predominates. On the other hand, at higher pHs and upon heating equilibrium will shift to the left and the dye will become colorless.

- The mechanism described above has been commercialized the most, and there is a wide variety of thermochromic materials available. Specifically, the commonly-employed thermochromic system is one wherein molecular rearrangement occurs by a reaction between an electron donating compound referred to as a color former and an electron accepting compound referred to as a developer.

- These compositions have the following advantages: (1) Thermochromic materials can be formulated for various colors; (2) The thermochromic materials gives a high color density; and (3) Depending on the kind of solvent, the color change temperature can be set over a wide range of low to high temperatures.

- To summarize, thermochromic materials of this type generally comprise an electron donating compound, an electron accepting compound, and organic solvents to control the temperature and sensitivity of the thermochromic effect. It can be appreciated that since thermochromism is an equilibrium reaction, the two component systems can be very sensitive to their environment and hence are generally encapsulated to make them amenable to deployment in different formulations. See, e.g., U.S. Pat. Nos. 4,028,118; 4,421,560; 4,425,161; and 4,717,770.

- It can be seen that there are a wide variety of thermochromic materials but which are generally very sensitive to their physical and chemical environment, which can comprise solvents, polymeric resin binders, stabilizing additives, pigments, dyes etc., which if not controlled, can quickly result in a degradation of the degree of color change, or even complete loss of thermochromic performance. Even for the case when thermochromic materials are encapsulated, to enable greater formulation flexibility for application to various substrates deploying a variety of techniques, the materials are still quite sensitive to their physical and chemical environment since the encapsulant is still porous. For the use of these materials as envirochromic materials that serve as indicators, as described above, it is essential for the color change to be perceived as vibrant.

- Even if the chemical environment does not impact the thermochromic materials, it can impact the capsule material. For example, the solvent can swell the polymeric capsule wall, thereby making it a scatterer of electromagnetic radiation. In cases where thermochromic materials are used as an optical switch, the changed color state will appear white and/or hazy instead of clear.

- For single layer constructions, even if the thermochromic material environment is carefully selected so that the thermochromic performance is not degraded, the solvents used can leach harmful materials from the substrate over which these materials are applied.

- Even though progress has been made over the years in expanding the colors and temperature ranges available, since thermochromic materials have generally been deployed as single layer applications, the color gamut is still fairly limited. With single layer embodiments, pigments are added to colorants in order to expand the range of colors that can be achieved. However, when color results from absorption of electromagnetic radiation, creating colors with combinations of thermochromic materials of limited color range, and pigment colorants, is still quite restrictive in the range of bright colors that can be achieved.

- Additionally, for outdoor usage, thermochromic materials are not only subject to photolytic degradation but by virtue of their sensitivity, need to be protected from mechanical forces such as abrasion, etc.

- Specific thermochromic materials and mixtures of thermochromic materials will need to be adapted to provide the requisite color change. Thermochromic materials usually exist as solids or liquid crystals in a carrier medium.

- When thermochromic materials are used as an optical switch, the theromochromic material needs to be formulated with clear resins and solvents that do not interact. Vibrant color layer formulations using solvents that do not leach are also desired.

- Outdoor usage of thermochromic objects also necessitates good adhesion to substrates and mechanical toughness such as scratch resistance, etc., specific requirements being dictated by the application.

- Accordingly, in view of the above, there is a need for thermochromic materials and thermochromic objects created from such materials that can serve as safety indicators, fashion indicators, or create fun and entertainment by triggering temperature-activated color changes that are vibrant and impactful. The thermochromic objects can also be created in a variety of standard and emissive colors, also with high intensity. The thermochromic objects are also created to minimize photolytic degradation, do not degrade with moisture, and are mechanically robust, particularly in outdoor applications.

- It has now been found that formulations comprising an effective amount of thermochromic materials, at least one liquid carrier medium, at least one polymeric resin, and at least one formulation stabilizing additive, wherein said thermochromic materials are uniformly distributed within said formulation provide thermochromic formulations with high intensity and persistence.

- Accordingly, in one of its formulation aspects, the present invention is directed to a thermochromic formulation comprising an effective amount of thermochromic materials, at least one liquid carrier medium, at least one polymeric resin, and at least one formulation stabilizing additive, wherein said thermochromic materials are uniformly distributed within said formulation.

- In another formulation embodiment, the present invention is directed to a thermochromic formulation comprising an effective amount of thermochromic materials, at least one liquid carrier medium, at least one polymeric resin, and at least one formulation stabilizing additive, wherein said thermochromic materials are uniformly distributed within said formulation and wherein the theromchromic formulation has an FT of at least 90%.

- In one of its object embodiments, the present invention is directed to a thermochromic object comprising a performed article and at least one thermochromic layer, wherein the thermochromic layer results from the foregoing thermochromic formulations.

- In yet another object embodiment, the present invention is directed to a thermochromic object comprising a preformed article, at least one thermochromic layer, and at least one reflective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the reflective layer results from a reflective formulation, wherein the reflective layer is proximal to said preformed article, and wherein said thermochromic layer is distal to said preformed article.

- In yet another object embodiment, the present invention is directed to a thermochromic object comprising a preformed article, at least one thermochromic layer, at least one reflective layer, and at least one protective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the reflective layer results from a reflective formulation, wherein said protective layer results from a protective formulation, wherein the reflective layer is proximal to said preformed article, and wherein said protective layer is distal to said preformed article, and wherein said thermochromic layer is between said reflective layer and said protective layer.

- In yet another object embodiment, the present invention is directed to a thermochromic object comprising a preformed article, at least one thermochromic layer, and at least one protective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the protective layer results from a protective formulation, wherein the thermochromic layer is proximal to said preformed article, and wherein said protective layer is distal to said preformed article.

- In one of its method aspects, the present invention is directed to a method for creating a thermochromic object, said method comprising the steps of obtaining a preformed article and applying to said preformed article at least one thermochromic layer, wherein said thermochromic layer results from the foregoing thermochromic formulations.

- In yet another method embodiment, the present invention is directed to a method for creating a thermochromic object, said method comprising the steps of obtaining a preformed article, applying to said preformed article at least one thermochromic layer, and applying to said preformed article at least one reflective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the reflective layer results from a reflective formulation, wherein the reflective layer is proximal to said preformed article, and wherein said thermochromic layer is distal to said preformed article.

- In yet another method embodiment, the present invention is directed to a method for creating a thermochromic object, said method comprising the steps of obtaining a preformed article, applying to said preformed article at least one thermochromic layer, applying to said preformed article at least one reflective layer, and applying to said preformed article at least one protective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the reflective layer results from a reflective formulation, wherein said protective layer results from a protective formulation, wherein the reflective layer is proximal to said preformed article, and wherein said protective layer is distal to said preformed article, and wherein said thermochromic layer is between said reflective layer and said protective layer.

- In yet another object embodiment, the present invention is directed to a method for creating a thermochromic object, said method comprising the steps of obtaining a preformed article, applying to said preformed article at least one thermochromic layer, and applying to said preformed article at least one protective layer, wherein the thermochromic layer results from the foregoing thermochromic formulations, wherein the protective layer results from a protective formulation, wherein the thermochromic layer is proximal to said preformed article, and wherein said protective layer is distal to said preformed article.

-

FIG. 1 illustrates how absorption of ultraviolet radiation by a molecule excites it from a vibrational level in the electronic ground state to one of the many vibrational levels in the electronic excited state, such as singlet states and triplet states. -

FIG. 2 is a Jablonski Diagram illustrating processes that occur between the absorption and emission of electromagnetic radiation. -

FIG. 3 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformedarticle 1 with athermochromic layer 2 applied thereto. -

FIG. 4 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformedarticle 1 with areflective layer 3 and athermochromic layer 2 applied thereto. -

FIG. 5 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformedarticle 1 with atheromchromic layer 2 and aprotective layer 4 applied thereto. -

FIG. 6 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformedarticle 1 with areflective layer 3, athermochromic layer 2, and aprotective layer 4 applied thereto. -

FIG. 7 is a stylized depiction of an embodiment of the invention whereby transfer technology is used to obtain the thermochromic object. -

FIG. 8 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformedarticle 1 with areflective layer 3, a firstthermochromic layer 2, a secondthermochromic layer 5, a firstprotective layer 4, and second protective layer 6 applied thereto. -

FIG. 9 is a stylized depiction of an embodiment of the invention whereby a thermochromic object is created using a preformedarticle 1 with areflective layer 3, a firstthermochromic layer 2, a secondthermochromic layer 5, and a firstprotective layer 4 applied thereto. -